Manufacturing faces its most significant transformation since the Industrial Revolution. Manual production systems are giving way to AI-powered automation at an unprecedented rate. This shift represents more than technological upgrade: it fundamentally changes how products are made.

The Current Manufacturing Landscape

Traditional manufacturing relies heavily on human operators. Workers monitor equipment, adjust settings, and make quality decisions based on experience and visual inspection. This approach works but creates bottlenecks.

Manual systems struggle with consistency. Human error affects quality. Labor costs continue rising. Production schedules depend on worker availability. These limitations push manufacturers toward automation.

AI-based production systems eliminate these constraints. Machines operate continuously. Algorithms make decisions faster than humans. Quality control becomes automated. Production scales without proportional workforce increases.

Core AI Technologies Transforming Production

Machine Learning and Predictive Analytics

Machine learning algorithms process production data to identify patterns. These systems predict equipment failures before breakdowns occur. Predictive maintenance reduces unplanned downtime by up to 50%.

Algorithms analyze sensor data from machinery. Temperature fluctuations, vibration patterns, and power consumption indicate potential issues. The system schedules maintenance during planned downtime rather than responding to failures.

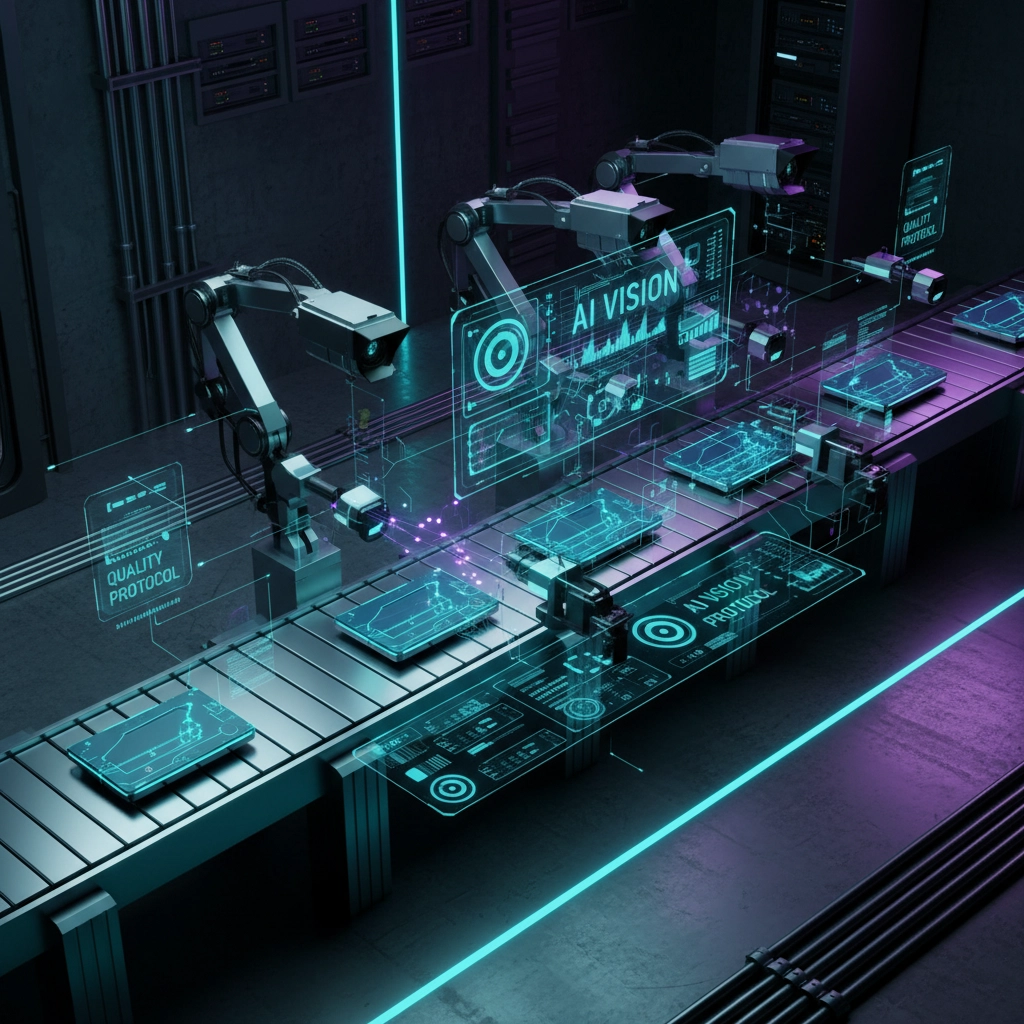

Computer Vision for Quality Control

AI-powered cameras inspect products at production speed. Computer vision systems detect defects smaller than human eyes can see. These systems maintain consistent quality standards across entire production runs.

Real-time inspection catches problems immediately. Defective products are removed before reaching customers. Quality control becomes proactive rather than reactive.

Natural Language Processing

NLP systems process maintenance logs and production reports. These algorithms identify recurring issues and suggest improvements. Operators communicate with systems using natural language commands.

Voice-activated controls allow hands-free operation. Workers focus on complex tasks while AI handles routine communication and documentation.

Production Scheduling and Resource Optimization

AI agents collect real-time data from multiple sources. IoT sensors, ERP systems, and supply chain inputs feed optimization algorithms. Production schedules adjust automatically when conditions change.

Equipment failures trigger immediate schedule reorganization. Available machines receive redistributed workloads without human intervention. Material delays cause automatic production sequence adjustments.

Resource utilization improves significantly. AI calculates optimal machine usage, material allocation, and workforce deployment. Waste decreases while output increases.

Key Benefits of AI-Based Production

Increased Efficiency

Automated systems operate 24/7 without breaks. Production rates increase by 20-30% on average. Setup times decrease through automated tool changes and parameter adjustments.

AI systems identify bottlenecks in real-time. Production flows optimize continuously based on current conditions. Throughput improves without additional equipment investment.

Cost Reduction

Labor costs decrease as automation handles routine tasks. Energy consumption optimizes through intelligent system management. Material waste drops through precise control and quality monitoring.

Maintenance costs reduce through predictive scheduling. Emergency repairs become rare events. Equipment lifespan extends through optimal operating conditions.

Enhanced Quality

Consistent parameters eliminate human variability. Automated inspection catches defects earlier in production. Quality metrics improve across all product lines.

Statistical process control becomes automated. Systems adjust parameters to maintain specifications. Customer complaints decrease while satisfaction increases.

Scalability

AI systems handle increased production volumes without proportional resource increases. New product lines integrate quickly through adaptive algorithms. Multi-facility operations coordinate seamlessly.

Production complexity no longer creates management challenges. AI handles intricate scheduling and resource allocation across global manufacturing networks.

Implementation Challenges

Initial Investment

AI-based production systems require significant upfront capital. Equipment upgrades, software licensing, and integration costs create barriers for smaller manufacturers.

ROI typically occurs within 18-24 months. Long-term benefits justify initial expenses for most operations. Financing options help manage cash flow during implementation.

Workforce Transition

Employee roles change dramatically during automation implementation. Manual operators transition to system monitors and problem solvers. Training programs become essential for successful transformation.

Job displacement concerns require careful management. Companies that invest in worker development achieve better outcomes. New roles often provide higher wages and better working conditions.

System Integration

Legacy equipment integration presents technical challenges. Different systems use incompatible communication protocols. Data silos prevent optimal AI performance.

Modern integration platforms solve compatibility issues. APIs connect diverse systems and equipment. Cloud-based solutions provide scalable integration options.

The Role of Real Estate in Manufacturing Automation

Manufacturing facilities must adapt to accommodate AI-based production systems. Smart factories require different spatial arrangements, power infrastructure, and connectivity solutions.

Real estate professionals specializing in industrial properties need understanding of these requirements. Automated production systems influence facility design, location selection, and lease negotiations.

PWRU’s intelligent platform helps real estate professionals navigate these complex industrial property transactions. AI-powered insights support decision-making for manufacturing facility investments.

Future Trends in AI Manufacturing

Digital Twins

Virtual replicas of production systems enable simulation and optimization. Digital twins test changes before implementation. Production parameters optimize through virtual experimentation.

Collaborative Robots

Cobots work alongside human operators safely. These systems combine human creativity with AI precision. Manufacturing becomes truly collaborative between humans and machines.

Edge Computing

Processing moves closer to production equipment. Response times decrease while reliability increases. Local AI systems operate independently of cloud connections.

Generative Design

AI creates optimized product designs and manufacturing processes. Generative algorithms explore design possibilities beyond human imagination. Production methods optimize automatically for specific requirements.

Making the Transition

Successful AI implementation requires strategic planning. Companies should start with pilot projects in specific production areas. Gradual expansion allows learning and adjustment.

Partner selection proves critical for success. Choose vendors with proven manufacturing AI experience. Support services and training capabilities matter as much as technology features.

Employee engagement ensures smooth transitions. Involve workers in planning and implementation. Address concerns openly and provide comprehensive training.

Measuring Success

Key performance indicators track automation benefits. Production throughput, quality metrics, and cost per unit provide baseline measurements. Downtime frequency and maintenance costs show operational improvements.

Customer satisfaction and delivery performance indicate market success. Employee safety and job satisfaction metrics ensure balanced outcomes.

Regular assessment guides continued optimization. AI systems improve continuously through machine learning. Performance gains accelerate over time.

Conclusion

The shift from manual to AI-based production systems represents manufacturing’s future. Companies that embrace this transformation gain competitive advantages in cost, quality, and flexibility.

Success requires strategic planning, appropriate technology selection, and workforce development. The benefits justify the investment for manufacturers ready to modernize operations.

Real estate professionals supporting industrial clients must understand these trends. Manufacturing automation influences facility requirements and investment decisions across the sector.

For real estate professionals seeking competitive advantages in industrial markets, PWRU’s AI-powered platform provides the insights and tools necessary to excel in this evolving landscape.